In the previous blog, we

discussed IOT (Internet of Things) impact to consumers and challenges in data

management. This blog focus on the various industries impact of IOT and how it

is revolutionizing them. Later we also discuss the importance of applying the

data management principles for improving the outcomes.

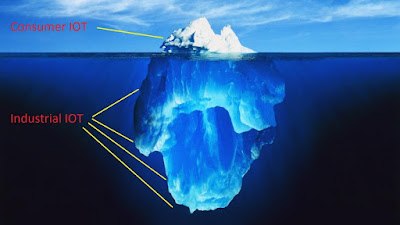

Consumer IOT made the

significant impact by providing valuable services to customers with many smart

devices makes life easy for the users. But commercial usage of IOT adaptation

might be slow but there is a potential to disrupt and revolutionize the

industries and solve many of the business challenges they never had solutions

in the past. As shown in the visual of ice burg the Industrial/commercial

IOT is very large with many solutions

like smart sensors, smart buildings, smart factories, digital supply chains.

Industry 4.0

The world of manufacturing is going thru major

disruption and revolutions which is called as

Fourth Industry revolution.

First industry revolution which happened till

the eighteenth century where availability of steam and water. Availability of

steam provided the first mechanization of the world. Hand production methods

moved towards to machines. Textile production improved productivity, steam

machines provided better transportation . Second industry revolution started in

the early nineteenth century with innovation and adaptation of electricity and

improvement of the manufacturing process of assembly lines. This revolution

moved towards mass production of goods. Availability of transportation

facilities to provide these goods to

sell across the country or even world.

The assembly lines process managed might be a paper-based process but

still efficiently deliver product in mass scales like hundreds of cars in a

month or thousands of soup cans. The mass production process even went in the

agricultural process of invention of better seeds by GMO, drift irrigation,

supply chain to reach product in the market intern able to reach all kinds of

foods on everybody's kitchen tables.

After the invention of the

computer and software started third industrial revolution improved the

industrial engineering to next phase of improvements. Moving paper based

process into computer applications, automation of process all improved overall

performance which improved output. Automation of the production, which improved

productions worldwide and made mass production more efficient. Now the world of

manufacturing going thru next revolution. The fourth industrial revolution,

also termed Industry 4.0, is being characterized as an increasing digitization

and interconnection of value chains and business models. Industry 4.0 creates

Smart Factories and is based upon cyber-physical systems allowing the

manufacturer to control the entire production from one platform. Industry 4.0 involved achieving total

connectivity with IOT (Internet of things) which also called industry internet. Industry 4.0 makes the existing manufacturing

applications increase the complexities in very significant level which

involving adapting new machinery or changes to existing physical systems. With

the emergence of big data platforms where they can collect the massive amount

of data and as well as intelligent devices which can collect and send a large

amount of data paired together comes with the new generation of software

applications which are a lot more intelligent with least amount of human

interference.

In short, whether it is a jet

engine, turbine, commercial conveyor belts when connected with smart sensors

sends data in real time can help to track, optimize, predict what to repair,

when to repair and even when to replace. This will change how manufacturing

industries operate be supporting their large and expensive machines. For

example, GE who is known to build large Jet Engines, Turbines are looking to

digitize their operations to improve their productivity as well as their

customers. Also Electrical engines in

cars with many smart sensors taking cars close to driver-less cars.

Smarter Devices /Machines

Many

existing Machines are integrated with external IOT devices which collect a lot

of information and send to central IOT application. A smart Nest thermostat

will help to operate the HVAC systems more efficiently and also collect

information about Air conditioner performance. Next level of HVAC systems is

coming with inbuilt IOT chip which can help to operate the system, collect

health data, diagnosis and selfheal the systems. New generation turbine has built in 200 plus

sensors collect a large amount of data helps to operate more efficiently and

manage its maintenance schedule.

Whether it is Industry distribution network or

Factor Floor there will be a lot of smart sensors gathering a large amount of

information and alerts any changes significantly impact the outcome, many of

these devices can be operated over the internet thru an IPAD, kiosk or Laptop.

With all the real-time information and instructions efficiently processed could

improve processing efficiency very significantly also reduce human interaction

or manual work.

Many times in factory floor

some of the machines are critical for the production process and if any

breakdown will stop the production. When machines break down technicians want

to fix the machine with very limited data and spend a lot of time

troubleshooting to find the root cause. Due to the criticality of the machine

sometimes these are replaced even they are operating in good condition because

there is no way they know when it is time to replace. Machine replacement cycle

is based on the usage duration not the status of the machine at the current

state. But the smart machines will constantly send health diagnostics and

performance data which could help to easily identify the problems with the

machinery. Also with all the information from IOT machines can gather health

information and could even heal very trivial problems without a technical get

involved.

Smart Meters

Utility companies had the

major technological revolution by introducing smart meters which can collect

the usage data and send to the Local utility company in very real time.This

information can help to optimize the distribution of utilities and also evolve

incentives to change the usage patterns. The real-time energy usage data can

help to identify fallouts, energy loss etc.. This gives the tremendous ability

for the utility company to have more accurate energy forecast, efficient

distribution. The next level of revolution could be capturing data of various

circuit breakers to identify inefficient appliances and suggest customer on

replacing them. The smart utilities,

smart sensors, smart devices could lead to smart buildings which have higher

energy efficiency and comfortable environment for the customers. Also,

management of facilities is a lot more efficient with smarter devices around

over the Internet/Intranet.

Smart Factories

Automated process control,

real-time production monitoring, real-time integrated manufacturing and

environmental conditioning/monitoring are made possible because of IOT devices

adoption, the platform for able to consume a large amount of data and analyze (

Big data platform). Part of industry 3.0

moved many manual processes into computer applications but still managed by

Factory operators and quality control also manual process in some cases. All of

these are slowly moving to automation of business process with many health and

quality information from the machines collected, analyzed and decisions are

made in control centers. Smarter

logistics, smarter Machines/Robots, smart grids, smart buildings, smart sensors

and smarter controls (Kiosks, control center, mobile applications) are making

factories optimizing and improving productivity least amount of labor costs. In

short smart factories, revolution is fueled by IOT devices and large data

platforms.

Similarly, supply chains are

optimizing with total connectivity between suppliers, warehouse, Factory

(Production), distributors, consumers with real-time information. This helps to

move forecasting model to close to real time demand model, real-time inventory

management, accurate logistics and overall revolutionize the manufacturing and

retail industries.

Now let’s discuss about “Data Management”

With the industrial

revolutions brings the new set of software applications and a large amount of

data/information. These applications are

very different than conventional enterprise applications we are building from

last three decades. These applications connect with devices in real time and

gather information in very real time at times many gigabytes of data for every

hour. Most of these applications have high scalability, high availability,

demanding and critical business needs. When hundreds of these devices

communicate in very real-time required sub-second response times and at times

in the range of thousands of Transactions of seconds. Also, devices could be

set up in the very large geographical area so that forces to keep these IOT

applications running in cloud-based infrastructure (sometimes it could be even

on a private cloud).

The cloud-based IOT

applications also need to still connect with existing enterprise applications

(ERP, CRM, sales/marketing, customer service, etc...) and exchange data so the

IOT application operates to fulfill the customer needs. In last thirty years,

the enterprise application collected lots of data in application and current

data management methodology segregates this data into two groups, Master data,

and Transactional data. Master data

tells who is the customer, where is the location and what is the product.

Transaction data will be all the operations using customer data like customer

purchases, customer support requests, customer browsing history and much

more. In this environment, Transactional

data is typically 100 times of master data but still, master data is critical

to better understand and analyze Transactions for better business decisions.

If you look at below diagram

wherein current data ecosystem without IOT devices where current enterprise

applications focus on master and transactional data, but device usage data

never captured by the application as all those are the manual and user-driven

process. The usage data if they

collected could be the larger volume than transactional data. The usage data

might have lot more critical information to help enterprise operate

efficiently, improve the device to perform better. Before IOT there is no easy way to collect the usage

data and the industry 4.0 enabled to collect usage data and also automate the

device usage.

Data organization Before IOT

Data organization with IOT

As you could see in the

diagram of "Data Management with IOT devices" where IOT applications

are collecting the usage data will change the data management paradigm. The

usage data still need to connect with Transactional data and master data to

give the complete context of the information. The IOT device data still need to

understand the customer, location, and device.

Even smart devices will be

maturing on both hardware and software design and implementation. We all heard

of multiple generations of the same device and sometimes even have subversions

of the hardware of the same device in the usage. Similarly, there are multiple

versions of firmware exist which is communicating to the central IOT Cloud

application. To understand the

interactions between the device goods to, it is very important to know the

right hardware and software versions the device running. Next Similarly we need

to know where the device operating accurately, also who is the customer and

users of the device. The device could change locations or change the

users/customers.

All these lead to the

importance of Master data and managing it with MDM methodology and then

integrate the MDM data with Transactional and usage data. So it is important to

understand the intersection between these different elements of data and plan

enterprise echo system where all of these can co-exist.

When an enterprise already

invested in Enterprise operational systems like SAP ERP, CRM and many other

sales, marketing, customer service systems it is important to integrate with

the cloud applications and also their corresponding analytical platforms. Every

new sale, operational systems need to connect back to IOT applications. For

example, when a device gets registered first times, the device customer/user

get identified and connected to Enterprise customer master. Same time location

information also tied with the Device and customer. Whenever customer/location

changes they need to be updated in both IOT application and enterprise

applications. Enterprise applications provide support and IOT Cloud

applications should have consistent customer information related to the device.

In manufacturing plants, the devices could be

a machine in the product plant represented in ERP systems and the Information

from the device need to reflected into ERP systems so an enterprise can take

advantage of up to date latest information from the devices.